On September 8, 2021, we received a call from a customer in Shaanxi Province who was looking for a crawler-type tunnel drilling rig for use in coal mines. Considering the actual situation in Shaanxi where the pressure relief treatment of tunnels and the gas drainage treatment are difficult and the efficiency of gas drainage treatment is low, we recommended this crawler-type tunnel drilling rig for coal mines to the customer.

This crawler-type tunnel drilling rig for coal mines adopts a hydraulic mechanical jack control principle and is widely used in the expansion and cavity-making pressure relief of rock strata in coal mine tunnels, the expansion and support of soft rock in coal mines, the treatment of rock burst and roof unloading, as well as the bottom cavity-making project for gas prevention and control in high-gas and soft coal seams.

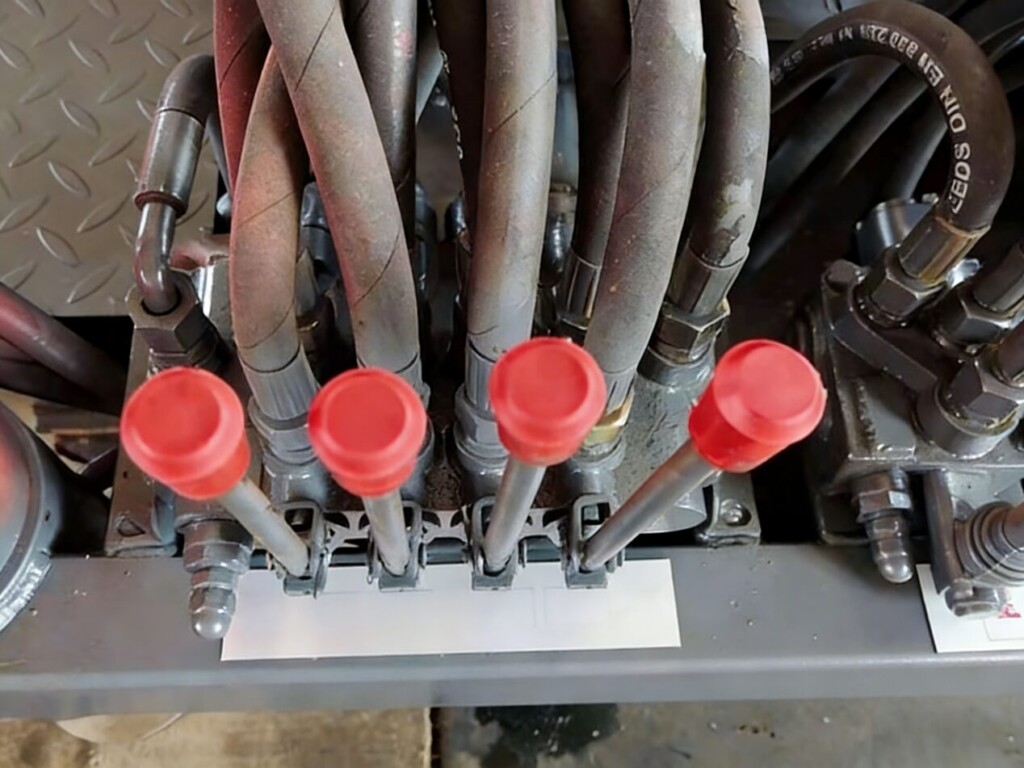

The crawler-type tunnel drilling machine for coal mines adopts the external hydraulic mechanical control principle, enabling the crawler-type tunnel drilling machine for coal mines to provide a hydraulic piston rod driving function. Corresponding control valve groups are arranged to control the hydraulic oil circuit, cooling water, and air. According to different construction needs, mechanical core rods and transmission drill pipes are combined for thrust-driven long-distance high thrust output. The mechanical enlarger opens actively at the target position of the tunnel excavation through the mechanical piston rod drill pipe, and closes actively after the tunnel excavation is completed. This significantly improves the external control level of the tunnel excavation engineering.

The crawler-type tunnel drilling machine for coal mines adopts the external hydraulic mechanical control principle, enabling the crawler-type tunnel drilling machine for coal mines to provide hydraulic piston rod driving function and arrange corresponding control valve groups. The main advantages of equipping the crawler-type tunnel drilling machine for coal mines are as follows:

Copyright © 2026 Yunyi Cang (Hebei) Supply Chain Management Co., Ltd. All Rights Reserved.